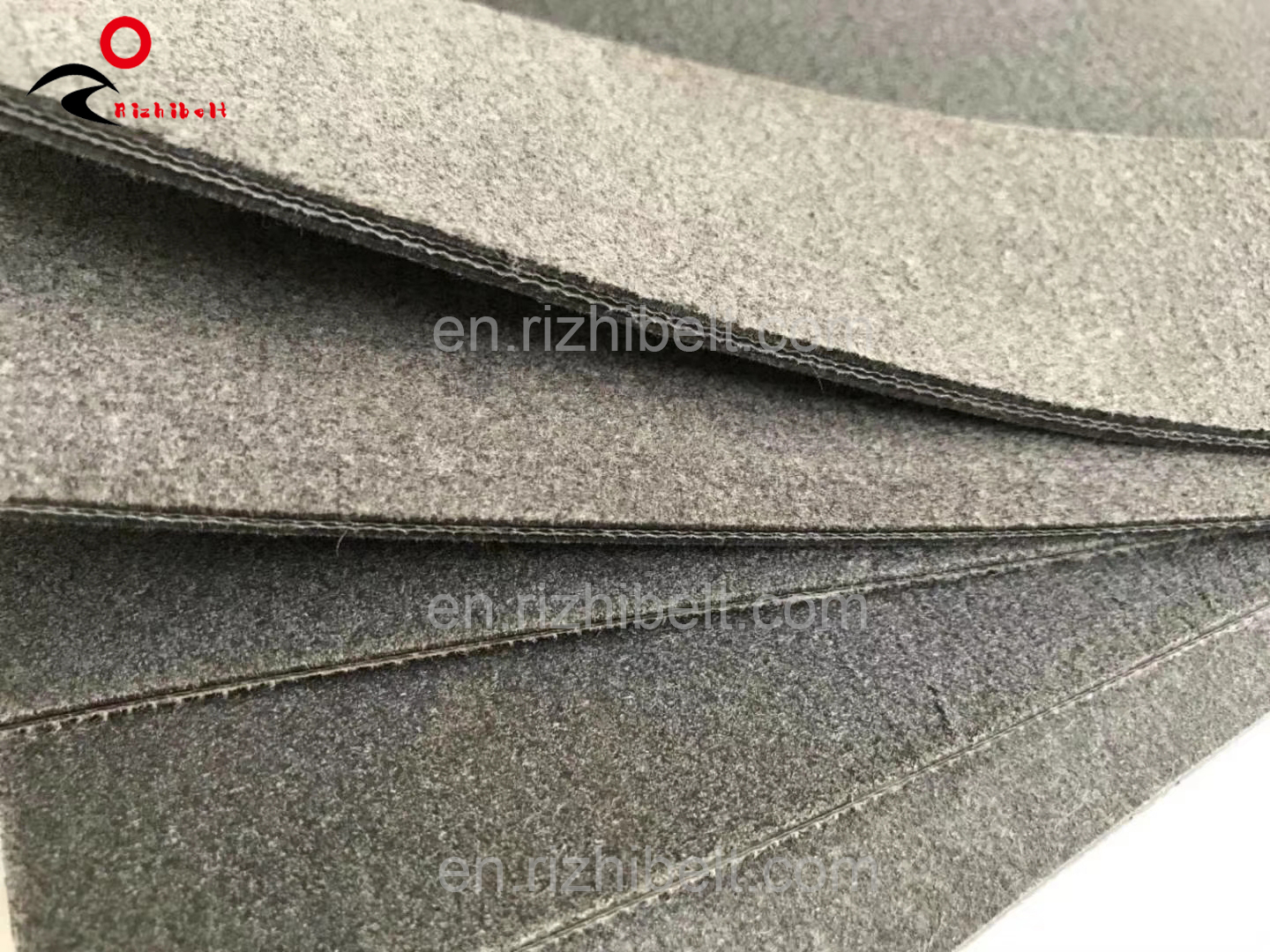

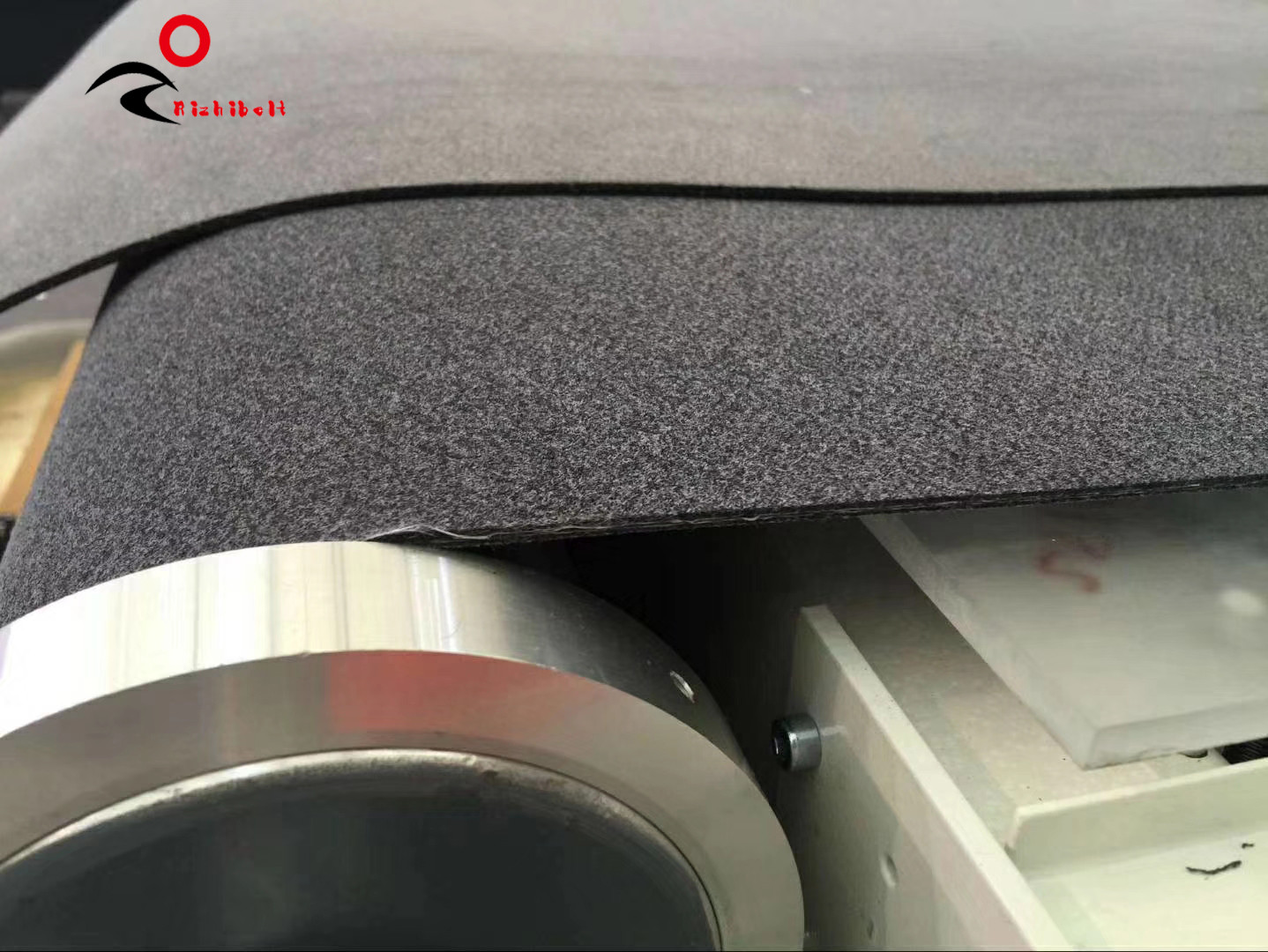

Different Thickness Transmission Felt Cutter Industry Used Novo Belt

Different Thickness Transmission Felt NN-17E/R40CT Cutter Industry Used Novo Belt

• Metalworking, mechanical engineering and the automotive industry: transport of sheet roll or single materials, assembly lines; transport of raw (unvulcanized) rubber compounds in hot / cold form (calendared or in dolls).

• Postal and logistics terminals, baggage transport systems at airports and railway stations.

• Packaging lines, cardboard lines; transportation of parts and housings of household appliances.

• Automatic slitting lines.

Distinctive features and advantages of the NN/17ER55 S=CPLUS

1.Product advantages:

Excellent high conductivity

High fixed elongation strength, low elongation of the belt in use, which improves the stability of the belt;

The surface is made of soft material with good abrasion resistance, which ensures the flatness of the product during the conveying and cutting process.

High impact resistance to prevent falls due to impact

Good breathability, can absorb air, prevent the product from floating during transportation due to lightness

1).Cut resistant

2).Antiskid

3).Excellent operation performance

4).Good abrasion resistance

5).Low elongation

6).Antistatic

7).Excellent flexibility

2.Industry application:

Double-sided felt belts are used in: tire conveyor belts, logistics conveyors, metal plates, castings conveyors, etc.

3.Novo Belting Application:

Material: synthetic fiber

Conveyor type: endless conveyor

Applicable environment: wear-resistant, anti-static, non-slip, cut-resistant

Conveyor Felt Belt

• Resistance to wear, cut, heat resistance; non-soiling surface, semi-rigid under pressure.