How to Distinguish between PVC Conveyor Belt and PU Conveyor Belt

Date:2019-08-07 15:35:36 Browse :PU Conveyor Belt: PU environmental protection material: Polyurethane (PU) is used as the raw material for the production of conveyor belting. The formula of the product is scientific and reasonable. It can meet the food hygiene standards and can be in direct contact with food. The color is moderate and there is no smell. Widely used in the food industry or the food sector to transport bulk, canned, packed into boxes of food, biscuits, candy, fruit and vegetable processing, poultry and meat processing and other related industries.

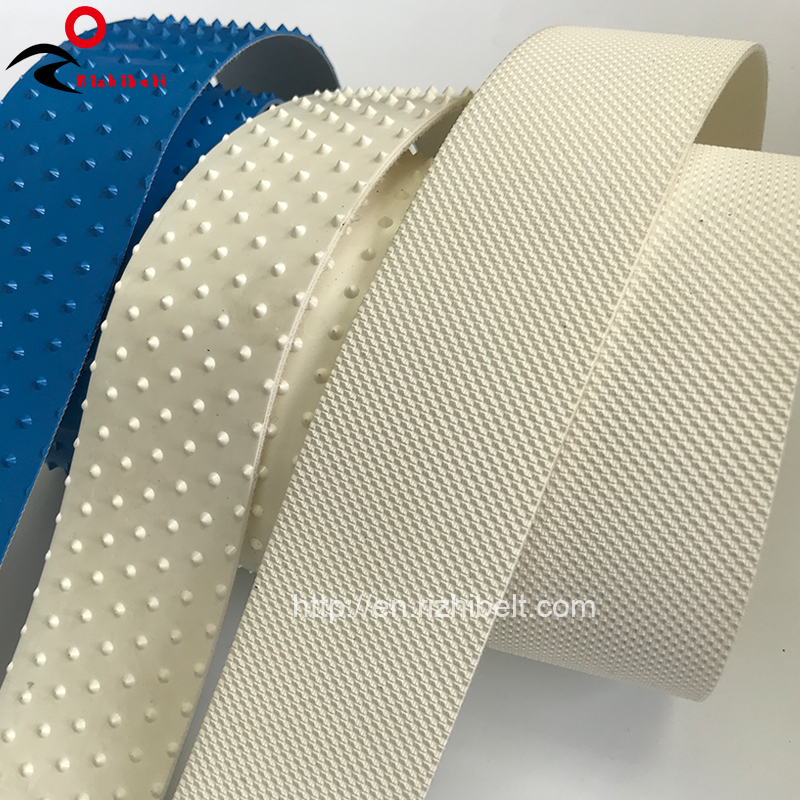

PVC Conveyor Belt: belt body is good in elasticity and not easy to be deformed. It is made of high-strength and high-quality cotton, nylon and polyester canvas as the core. It is made of pure natural rubber and non-polluting compounding agent to make white or light color, no pollution, and does not affect the food hygiene odor coating. PVC conveyor belt product formula design is reasonable, in line with health indicators, moderate color, light and durable. PVC conveyor belts are suitable for the food industry or the food sector to transport bulk, canned, packaged food or food to a large particle size of 400, and the delivery volume can range from 1 cubic meter / hour to 6000 cubic meters / hour.

PU is food-grade. If the food industry chooses PVC, it will not be long before Conveyor Belts will be plasticized, and small cracks will appear on the surface. Some plasticizers will be plasticized into food. Secondly, the PU material itself is resistant to acid and alkali, and the effect of PVC is much worse. Therefore, once the environment is acid and alkali, the life of the PVC is greatly reduced, and the cost and trouble of replacing the belt are greatly reduced. The pulling force and strength of PU are much larger than PVC, so if the drum motor is not big enough, it needs to use 2.0 thick PU, its strength should be at least 4.0PVC strength to replace.

How to distinguish the conveyor belts of these two materials?

1. Test the burning taste of the conveyor belt with fire: When the PU is burning, it has a certain fragrance, and the smell is small. After burning, it becomes a black viscous liquid. After the hand touches, there is adhesion and there is drawing. When PVC is burned, the food grade PVC Conveyors Belt has a large smell and is very rushed. After burning, it turns into carbonization, which is hard. After handcuffs, it will become powder and PU will burn less smoke. It mainly uses white smoke. Occasionally, there is smoke because it does not burn. full. PVC burns smoke, all black smoke.

2. Fold the resilience of the conveyor belt by hand: the PVC conveyor belt rebounds slowly after folding, and PU conveyor belt rebounds quickly.

3. Test the scratch resistance of Conveyors Belting with nails: The surface of the PVC conveyor belt is easy to have dents, and the original sample is slower, and the PU conveyor belt has no dents.

The light conveyor belt is light, efficient, environmentally friendly, and does not slag. It has gradually replaced the use of rubber and other materials in many industries. With the gradual expansion of the amount, PVC conveyor belts and PU conveyor belts can be seen everywhere. Light conveyor belts are mainly divided into PVC conveyor belts and PU conveyor belts. The appearance of these two materials is very similar. It is really difficult to distinguish without similar experience, and the prices of these two belts are very different.

Through the above analysis of the PVC conveyor belt and the PU conveyor belt, I believe that everyone has a new understanding of these two conveyors. If you want to know more about the other aspects of Logistics Conveyor Belt PVK, High Performance Flat Belt, Heavy Conveyor Belt, cutting machine conveyor belt etc.Welcome to visit: http://en.rizhibelt.com